Eilbeck about to deliver next two Cranes to the NorthConnex Project

The Australian Government is investing $50 billion in thousands of road and rail projects around Australia under its Infrastructure Investment Programme.

Investing in better road and rail connections will make it easier for freight to move across Australia – whether it is around our cities, our regions or within states and territories. This will deliver economic benefits by ensuring the economy remains competitive and goods can move effectively.

Factory Acceptance Testing

The Infrastructure Investment Programme will redefine the way people move around not just their streets and suburbs, but around entire cities. The multi-billion dollar WestConnex project combined with the $3.6 billion Western Sydney Infrastructure Plan will significantly improve traffic flow in Sydney all the way from Penrith into the city.

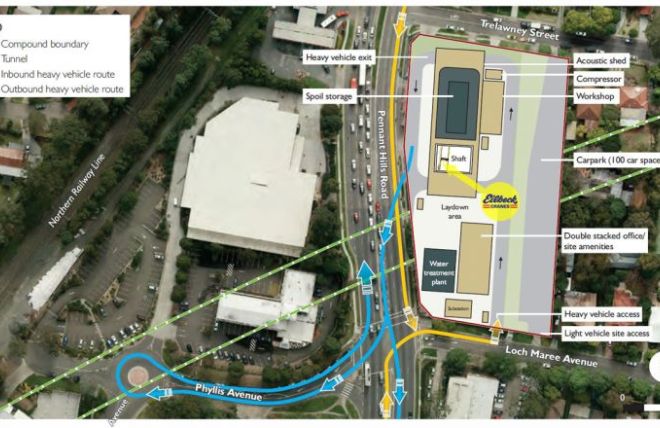

NorthConnex tunneling project tender Lendlease – Bouygues Joint Venture has broken the project into four discrete job sites which will all service tunnelling operations. Each site will ultimately have access to four mainline and ramp tunnel faces. With this setup, there are 3 shafts as an intermediate access to the tunnel. Each shaft sizes are 16m by 12m and the depth of the shafts are varies due to the alignment and gradient of the proposed tunnel.

With the shaft arrangement, the use of an overhead crane system has been determined to be the most efficient method for 2 major purposes. The first is to load and unload heavy machineries into the shaft taking into account size and weight of varies excavation plants and the surrounding project constrains. And the second is to remove excavated materials out from the shaft.

Crane being fabricated at Eilbeck's Moorlands factory in Ingleburn, NSW

Eilbeck Cranes have been selected to supply the required gantry cranes from among the most renowned companies in the world, owing to the proven track record for timely delivery of quality products in similar projects.

After having supplied and commissioned gantry cranes to Wahroonga north site and M2 southern site, Eilbeck is ready to deliver two more cranes to the Wilson and Trelawney site.

The first crane for the Wilson Site is a massive 25m span double girder crane equipped with the 100t main hoist and 10t auxiliary hoist with man riding capabilities.

100/10t hoist on it's way out of the factory

The whole crane has been built at Eilbeck Moorlands factory including the spliced 9m hoist drums machined at our new state-of-the-art Machine Shop at Lancaster Street in Ingleburn, Sydney.

The crane will assist in lifting excavation equipment at the NorthConnex Wilson Site and support the tunnel boring machine in kibbling the projects muck.

Eilbeck’s recent strategic move to shift the whole production to be done internally has proven to work out beyond initial expectations with the Machine Shop running full swing, providing cost efficient top quality components without the need to rely on overseas sub-contractors and suppliers. This in turn enables us to comply with ease and have full control over the final product being fabricated in accordance with all Australian and International standards, exceeding initial requirements and providing our clients with top quality products.